Europe, Middle East, Africa (EMEA)

Asia Pacific (APAC)

Americas (AM)

- Automated Mailer Bags and Pouches

- Bubble Bags

- Bubble Bundles

- Fabricated Foams

- Flooring Underlayment

- Instapak® Foam Packaging

- Korrvu® Suspension and Retention

- Mailers

- On-Demand Inflatables

- Paper Void Fill Solutions

- Paper Wrapping Solutions

- Recycled Bubble

- Shrink Films

- Surface Protection Foams

- Temperature Assurance Bags and PUR

- Advanced Customer Training

- AUTOBAG® Product Resource Library

- AutoLabel Software Tools and Support

- Customer Service

- Custom Bagging Machine Applications

- Custom Engineering and Integrated Systems

- Factory Service Repair Center

- Field Service and Preventive Maintenance

- Financing and Payment Options

- Graphics, Art & Imaging for Custom Branded Bag Packaging

- Systems Advantage: The Total Systems Approach to Bag Packaging

- Technical Phone Support

Technical Services

SEE™ Advanced Maintenance Program

The ability to operate efficiently is heavily dependent on equipment running smoothly. Lost documentation, cost-cutting measures, and high employee turnover can easily lead to delayed or overlooked maintenance. If you wait until equipment fails to repair it, you’re likely losing critical production hours and risking unhappy customers.

The SEE™ Advanced Maintenance Program (AMP) is a proactive, preventive maintenance plan designed to increase uptime, enhance performance, and improve efficiency for select equipment models in the SEE™ Automation portfolio.

Program Features for Food Equipment

- The SEE™ Advanced Maintenance Program for food equipment is enabled by SEE™ Smart Link* technology, our proprietary connectivity solution that allows food processors to collect, store, analyze, and share operating data

- Developed and offered exclusively by SEE, this secure, cloud-based platform collects, stores, and analyzes real-time production data that can be used for monitoring and process control

- Data collected can also be used to improve efficiency and enhance performance against your custom metrics

- Regularly scheduled equipment audits

- Equipment reconditioning

- Catastrophic parts protection for rotaries

- Complimentary installation and use of SEE™ Smart Link (currently only available for rotary vacuum chamber models)

- Affordable monthly service plan keeps maintenance costs steady

- Reduced downtime as a result of fewer machine breakdowns

- Minimized disruption in production schedules

- Enhanced efficiency of equipment

- Reduced energy costs

- Service contracts available for machines that meet age condition requirements

- Available for select CRYOVAC® brand rotary vacuum chamber machines, vertical form-fill-seal machines, and the BL75 bag loader

Program Features for Protective Equipment

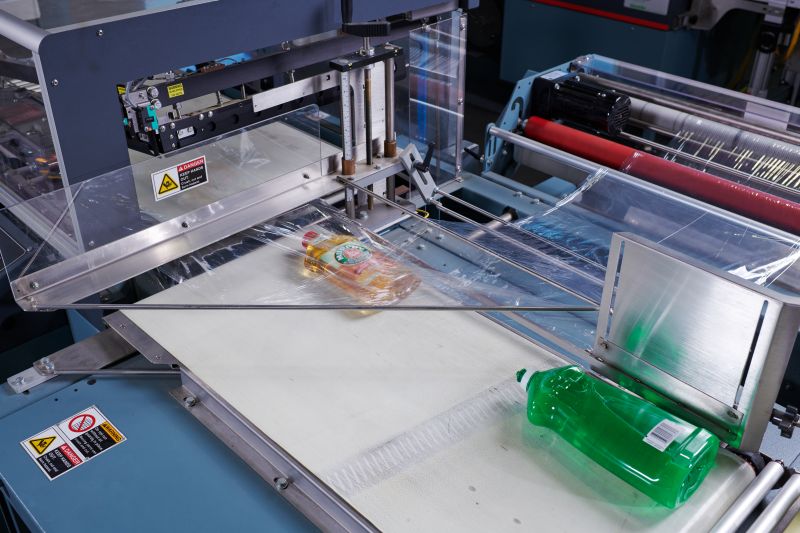

- The SEE™ Advanced Maintenance Program for protective equipment is available for select models in the SEE™ Automation portfolio

- Designed to reduce unplanned downtime, this program offers the benefits of a preventative maintence plan over a reactive maintenance plan

- Regularly scheduled equipment audits

- Base option available for all equipment models

- Available emergency service coverage on select plans

- Additional coverage options available for specified models

- Reduced downtime as a result of fewer machine breakdowns

- Increased customer satisfaction through timely and continuous production

- Enhanced efficiency of equipment with reduced energy and labor costs

- Improved performance helps determine new maintenance strategies to fit your operational needs

Find Your Automated Solution

More From SEE

Connect With Us

Get answers to common questions about our company, products, services, and beyond by filling out the form below. A dedicated representative will contact you soon to better understand and address your specific needs..

* All fields required

Thank You

Thank you for reaching out. We've received your information and will respond shortly. We appreciate your interest in Sealed Air.

Are you sure you want to cancel your submission?

Your information will not be saved.