Europe, Middle East, Africa (EMEA)

Asia Pacific (APAC)

Americas (AM)

- Automated Mailer Bags and Pouches

- Bubble Bags

- Bubble Bundles

- Fabricated Foams

- Flooring Underlayment

- Instapak® Foam Packaging

- Korrvu® Suspension and Retention

- Mailers

- On-Demand Inflatables

- Paper Void Fill Solutions

- Paper Wrapping Solutions

- Recycled Bubble

- Shrink Films

- Surface Protection Foams

- Temperature Assurance Bags and PUR

- Advanced Customer Training

- AUTOBAG® Product Resource Library

- AutoLabel Software Tools and Support

- Customer Service

- Custom Bagging Machine Applications

- Custom Engineering and Integrated Systems

- Factory Service Repair Center

- Field Service and Preventive Maintenance

- Financing and Payment Options

- Graphics, Art & Imaging for Custom Branded Bag Packaging

- Systems Advantage: The Total Systems Approach to Bag Packaging

- Technical Phone Support

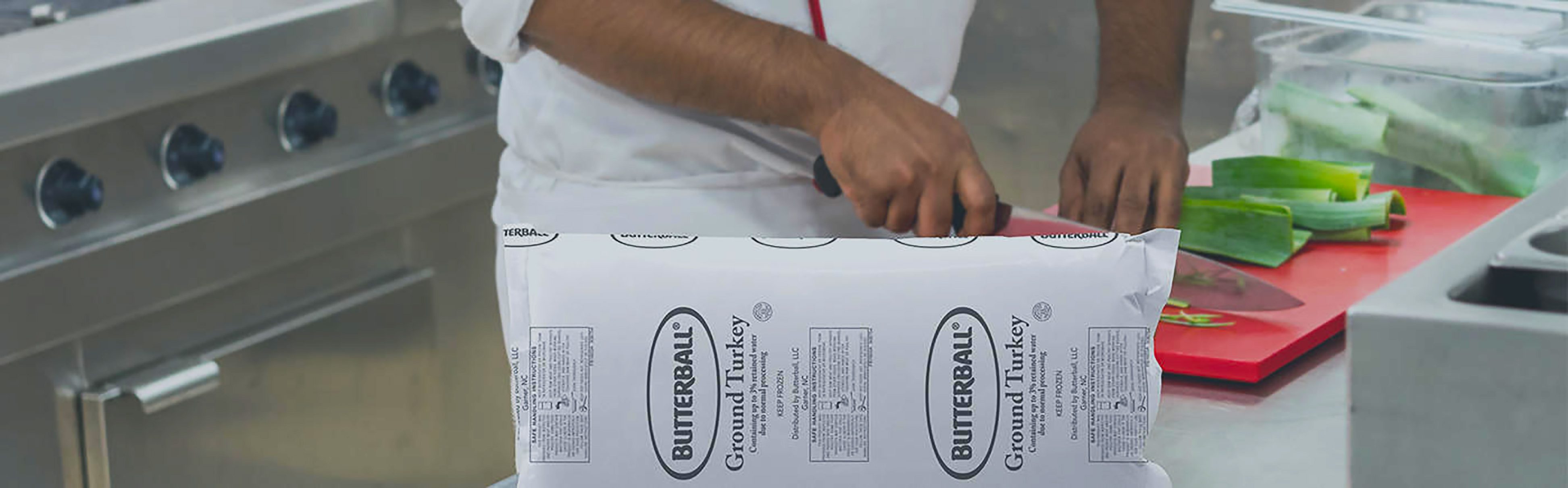

Butterball Foodservice Tackles Food Safety With CRYOVAC® Brand VPP

Challenge

For a number of years, Butterball used chub packaging with metal clips for their food service ground turkey products. Although the packaging was industry standard, metal clips presented a number of challenges including keeping track of the clips and making sure they did not end up in finished dishes.

Solution

As long-term partners in ground turkey packaging, Butterball turned to Sealed Air to explore alternatives to metal clip packaging. Sealed Air, having foreseen the issues with metal clips, had already successfully tested a clipless solution for beef and was able to quickly test the solution with ground turkey.

Sealed Air introduced Butterball Foodservice to CRYOVAC® brand Vertical Pouch Packaging (VPP) and Butterball instantly recognized the safety and quality advantages. “Food safety is as much a priority for Butterball as it is for our operators, and our new ground turkey packaging meets that need while also allowing chefs to create delicious dishes for their diners,” says Richie Jenkins, Butterball’s senior director of national accounts/marketing.

“Food safety is as much a priority for Butterball as it is for our operators, and our new ground turkey packaging meets that need while also allowing chefs to create delicious dishes for their diners.”

—Butterball’s Senior Director of National Accounts and Marketing, Richie Jenkin

Package Optimization

Product Integrity

Results

- Packages are safer throughout the supply chain with no risk of metal clips getting misplaced or inadvertently ending up in food

- Virtually all of Butterball’s ground turkey food service customers now receive their product in VPP

- Distributors and end users continue to view Butterball Foodservice as a leader in innovative packaging that solves operator concerns

- The new rectangular product shape is easier for food service operators to stack and takes up less freezer space

- The durable film stands up better to movement during shipping, preventing leaks and avoiding punctures while helping the ground turkey maintain its flavor and freshness

As the first turkey producer to move to VPP, Butterball Foodservice is, once again, demonstrating vision and innovation in their category — and it’s paying off. Both 5- and 10-pound foodservice packages are now safer from processor to distributor to back of house, with no risk of metal clips getting misplaced or inadvertently ending up in the meat and/or finished dishes. Distributors and end users are pleased that the clipless packaging eliminates any potential risk and the durable film stands up better to movement during shipment, preventing leaks, freezer burn and avoiding punctures while helping the ground turkey maintain its flavor and freshness. The new rectangular product shape is easier for foodservice operators to stack and takes up less freezer space. The proactive move to CRYOVAC® brand VPP is another way Butterball Foodservice is reinforcing their leadership as an innovator that solves operator concerns.

Connect With Us

Get answers to common questions about our company, products, services, and beyond by filling out the form below. A dedicated representative will contact you soon to better understand and address your specific needs..

* All fields required

Thank You

Thank you for reaching out. We've received your information and will respond shortly. We appreciate your interest in Sealed Air.

Are you sure you want to cancel your submission?

Your information will not be saved.