Europe, Middle East, Africa (EMEA)

Asia Pacific (APAC)

Americas (AM)

- Vertical Form-Fill-Seal Films

- Barrier Formable Paper Webs

- Overwrap Films

- Pouches range

- Pre-Opened Bags

- Tray Lid Films

- Vacuum Shrink Bags

- Vacuum Skin Packaging

- Bag-in-Box

- Shrinkable Rollstock

- Food Equipment

- AutoWrap Lite system

- Bagging and Loading

- Bag and Pouch Food System

- Bag-in-Box Fillers

- Drying Tunnel

- Food Packaging Shrink Tunnels

- Vertical Form-Fill-Seal Equipment

- Rotating Belt Conveyor

- Soft Vacuum Systems

- Vacuum Chamber Systems

- Vacuum Skin Equipment

- Automated Cartoning

- Automated Mailers

- Bubble Bags

- Bubble Bundles

- Films, Bags, and Pouches

- Foam Moulding Systems

- Construction Solutions

- Inflatable Pillows

- Inflatable Cushioning

- Inflatable Pouches

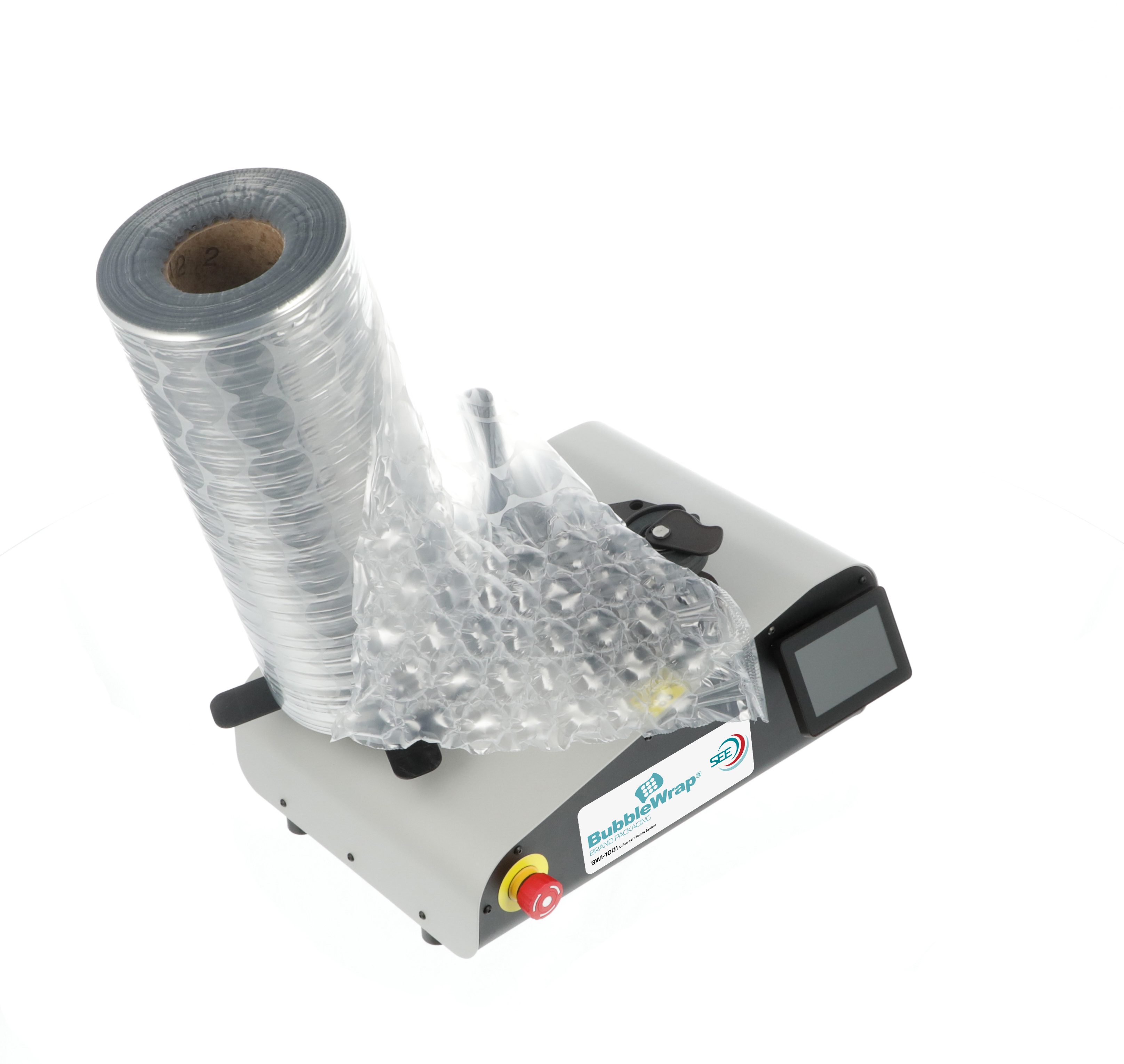

- Inflatable Cushioning System

- Inflatable Void Fill System

- Instapak® Quick RT®

- Instapak® Foam-In-Bag Systems

- Instapak® Speedypacker®

- Light Cushioning

- Paper Mailers

- Paper Cushioning System

- Manual Paper Void-Fill Solutions

- Paper Void-Fill Systems

- Paper Wrapping Solutions

- Performance Inflatables

- Polyethylene Sheets and Rolls

- Poly Mailers

- Recycled Bubble

- Recycled Inflatable Cushioning

- Suspension & Retention

- Shrink Films

- Recycled Content Inflatable Air Pillows

- Surface Protection Foams

- Temperature Assurance

- Textile Packaging System

- Universal Inflation System

- Aerospace and Defense

- Alternative Proteins

- Apparel and Accessories

- Automotive

- Bakery and Snacks

- Building & Construction

- Cheese & Dairy Foods

- Consumer Goods

- Electronics

- Food & Beverage

- Food Processing

- Food Service

- Fresh Beef, Pork & Lamb

- Fresh Produce

- Frozen Foods

- Healthcare & Pharma

- Industrial Parts

- Manufacturing

- Meal Kit Packaging

- Pet Care

- Poultry Packaging

- Ready to Eat Meals

- Seafood

- Soups, Sauces & Sides

- Liquid Food Products

- IoT Is Transforming Food Manufacturing

- Recycling and Reusing Packaging Materials

- 3 Packaging Mistakes Brands Should Avoid

- Are Your Recycling Efforts a Waste?

- Shippers Beware: Freight Costs Can Cost You Everything

- Sustainability Impact of E-Commerce Packaging

- Return Logistics Help for Online Retailers

- Tackle Dimensional Weight

- Fulfillment Complexity

- Consumers Need a Reset for Recycling

- Challenges of eFood Delivery

- Don’t Let Boxes Ruin Your Brand

- 4 Basic Ways to Improve Unboxing

- E-Commerce Demand Drives Change

- The Changing Face of the Retail Grocery Shopper

- Limited Touchpoints Ease Consumer Concerns

- Case-Ready Packaging Helps Offset Uncertainty

- Paper Remains Top Pick for Recyclable Packaging

- Unsealing Food Technology to Feed the World

- Shipping Trends Favor Parcels, Not Pallets

- Online Shopping Goes High-Tech — and High Risk

- Closing the Loop with Advanced Recycling

- 4 Reasons to Switch From Rigid to Flexible Packaging

- Nordic Food Retail

- EV Charger

- Certificate EN15343 Aneby

- Polyethylene Foams channels

- Polyethylene Foams customers

- Skin Packaging

- Korrvu solutions for packaging

- Meat Packaging Automation

- Bubble Wrap Appreciation Day

- The Environmental Impact of Damaged Products

- Making the Switch to Paper Packaging?

- Are You Ready for Intelligent Automation Solutions?

- Pack Station Solutions

- Solving Complex Fulfillment Challenges

- Let's Be Clear About Single-Use Plastics

- Reducing Food Waste Throughout The Global Supply Chain

- Podcast

- Ensuring Food Safety With CRYOVAC® Brand High-Performance Barrier Packaging

- How to Shift From Pallets to Parcels

- Coronavirus Vaccine and Testing Packaging Solutions

- Switch From Rigid to Flexible Liquid Packaging

- Guide to Packaging Automation

- Sealed Air Sustainable Packaging Guide

- Case-Ready: Ready for Anything

- Recycle-Ready Shrink Bags and Shrinkable Rollstock

- Recyclability Claims: What You Need to Know

- Manufacturer's Guide: Switching From Pallets to Parcels

- 5 Pitfalls to Avoid When Automating Your Packaging Hall

Improve Productivity With

Sealed Air Pack Station Solutions

Consumer Demands Continue to Pressure E-commerce Shippers

Growing consumer demands continue to put immense pressure on E-commerce companies to ship more orders in shorter time frames. Increasing labour to pack orders or expanding your warehouse footprint to help meet the demand isn’t an option for most – nor is it sustainable. The solution is to optimise your manual packaging process by taking incremental steps toward automation.

Did You Know?

Product pickers walk an average of 15 miles a day and efficiency in a packaging operation is rarely above 60%.

Automate Manual Packing Stations to Improve Fulfilment Productivity

For many E-commerce and fulfilment companies, the pick and pack process has a direct impact on warehouse productivity, business profitability and the satisfaction of warehouse employees and customers. Without methodically designed packaging stations that meet the demands of both warehouse managers and their packers, companies are at risk of:

- Difficulty with labour retention due to unhappy packers

- Higher packaging material costs due to inefficient and disparate packing methods

- Dissatisfied customers due to longer production lead times and slower order throughput

- Poor demand forecasting due to process unpredictability

- Worker injury due to non-ergonomic pack stations

Semi-Automated Packaging Systems That Meet Your Immediate Needs

You don’t have to jump to complete automation if you’re not ready. Automated packaging solutions can come in different, flexible sizes that meet your immediate needs. Semi-automated packaging solutions can address these risks without a large capital investment and can provide immediate ROI. Sealed Air offers a complete range of packaging materials and semi-automated equipment that adapt to your current operation, are easy to install, and make the most of every resource you have today.

Customer Case Study

Improving Operational Efficiency for Online Retailer, Fanatics

Fanatics is a global supplier of sports fan merchandise including football shirts, shorts, socks, baseball caps, mugs and other souvenirs. The majority of Fanatics packaging operation was handled manually, putting a strain on labour resources and slowing down order fulfilment. Fanatics turned to the AUTOBAG® brand 850S bagging and printing packaging system. The solution optimised existing resources, like labour and warehouse space, and streamlined its complex, high-volume E-commerce order fulfilment processes.

“The four AUTOBAG® brand 850S machines have transformed the way we pack items and are now handling about 75% of orders coming through the warehouse. Without this solution we would have struggled to have the space to keep up with rising volume levels."

- Andrew Crozier, Operations Manager at Fanatics

Featured Pack Station Solutions

Our pack station solutions are easy to install and integrate into your existing fulfilment environment with minimal downtime. By implementing our solutions in an optimised pack station, you'll see faster return on investment with higher order throughput, reduced damage rates and improved shipping costs.