Europe, Middle East, Africa (EMEA)

Asia Pacific (APAC)

Americas (AM)

- Vertical Form-Fill-Seal Films

- Barrier Formable Paper Webs

- Overwrap Films

- Pouches range

- Pre-Opened Bags

- Tray Lid Films

- Vacuum Shrink Bags

- Vacuum Skin Packaging

- Bag-in-Box

- Shrinkable Rollstock

- Food Equipment

- AutoWrap Lite system

- Bagging and Loading

- Bag and Pouch Food System

- Bag-in-Box Fillers

- Drying Tunnel

- Food Packaging Shrink Tunnels

- Vertical Form-Fill-Seal Equipment

- Rotating Belt Conveyor

- Soft Vacuum Systems

- Vacuum Chamber Systems

- Vacuum Skin Equipment

- Automated Cartoning

- Automated Mailers

- Bubble Bags

- Bubble Bundles

- Films, Bags, and Pouches

- Foam Moulding Systems

- Construction Solutions

- Inflatable Pillows

- Inflatable Cushioning

- Inflatable Pouches

- Inflatable Cushioning System

- Inflatable Void Fill System

- Instapak® Quick RT®

- Instapak® Foam-In-Bag Systems

- Instapak® Speedypacker®

- Light Cushioning

- Paper Mailers

- Paper Cushioning System

- Manual Paper Void-Fill Solutions

- Paper Void-Fill Systems

- Paper Wrapping Solutions

- Performance Inflatables

- Polyethylene Sheets and Rolls

- Poly Mailers

- Recycled Bubble

- Recycled Inflatable Cushioning

- Suspension & Retention

- Shrink Films

- Recycled Content Inflatable Air Pillows

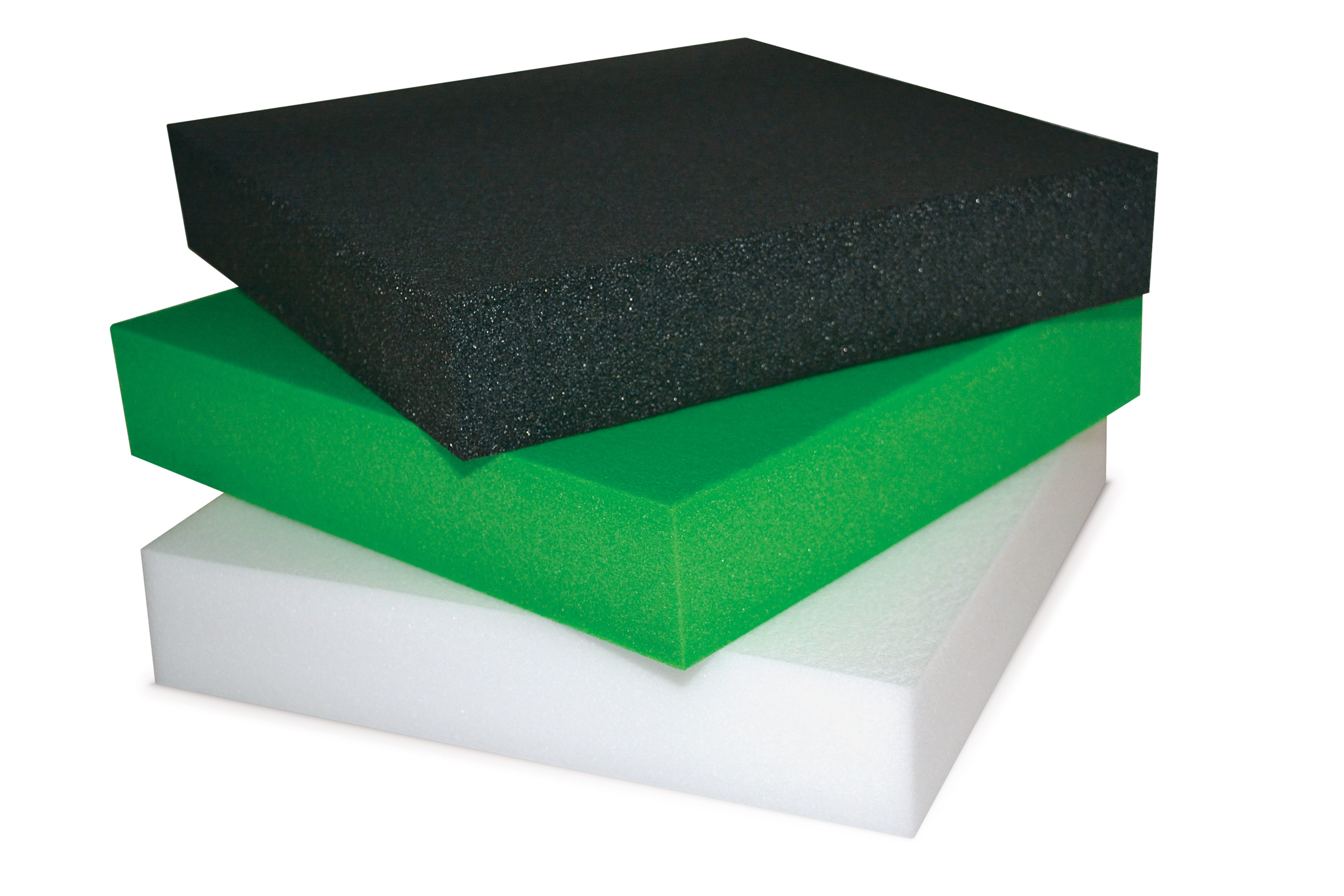

- Surface Protection Foams

- Temperature Assurance

- Textile Packaging System

- Universal Inflation System

- Aerospace and Defense

- Alternative Proteins

- Apparel and Accessories

- Automotive

- Bakery and Snacks

- Building & Construction

- Cheese & Dairy Foods

- Consumer Goods

- Electronics

- Food & Beverage

- Food Processing

- Food Service

- Fresh Beef, Pork & Lamb

- Fresh Produce

- Frozen Foods

- Healthcare & Pharma

- Industrial Parts

- Manufacturing

- Meal Kit Packaging

- Pet Care

- Poultry Packaging

- Ready to Eat Meals

- Seafood

- Soups, Sauces & Sides

- Liquid Food Products

- IoT Is Transforming Food Manufacturing

- Recycling and Reusing Packaging Materials

- 3 Packaging Mistakes Brands Should Avoid

- Are Your Recycling Efforts a Waste?

- Shippers Beware: Freight Costs Can Cost You Everything

- Sustainability Impact of E-Commerce Packaging

- Return Logistics Help for Online Retailers

- Tackle Dimensional Weight

- Fulfillment Complexity

- Consumers Need a Reset for Recycling

- Challenges of eFood Delivery

- Don’t Let Boxes Ruin Your Brand

- 4 Basic Ways to Improve Unboxing

- E-Commerce Demand Drives Change

- The Changing Face of the Retail Grocery Shopper

- Limited Touchpoints Ease Consumer Concerns

- Case-Ready Packaging Helps Offset Uncertainty

- Paper Remains Top Pick for Recyclable Packaging

- Unsealing Food Technology to Feed the World

- Shipping Trends Favor Parcels, Not Pallets

- Online Shopping Goes High-Tech — and High Risk

- Closing the Loop with Advanced Recycling

- 4 Reasons to Switch From Rigid to Flexible Packaging

- Nordic Food Retail

- EV Charger

- Polyethylene Foams channels

- Polyethylene Foams customers

- Skin Packaging

- Korrvu solutions for packaging

- Meat Packaging Automation

- Bubble Wrap Appreciation Day

- The Environmental Impact of Damaged Products

- Making the Switch to Paper Packaging?

- Are You Ready for Intelligent Automation Solutions?

- Pack Station Solutions

- Solving Complex Fulfillment Challenges

- Let's Be Clear About Single-Use Plastics

- Reducing Food Waste Throughout The Global Supply Chain

- Podcast

- Ensuring Food Safety With CRYOVAC® Brand High-Performance Barrier Packaging

- How to Shift From Pallets to Parcels

- Coronavirus Vaccine and Testing Packaging Solutions

- Switch From Rigid to Flexible Liquid Packaging

- Guide to Packaging Automation

- Sealed Air Sustainable Packaging Guide

- Case-Ready: Ready for Anything

- Recycle-Ready Shrink Bags and Shrinkable Rollstock

- Recyclability Claims: What You Need to Know

- Manufacturer's Guide: Switching From Pallets to Parcels

- 5 Pitfalls to Avoid When Automating Your Packaging Hall

Foam Moulding Systems

SEALED AIR® brand foam moulding systems produce custom shaped Instapak® cushions.

01 Overview

SEALED AIR® brand foam moulding systems produce custom shaped Instapak® cushions.

SEALED AIR® brand Instapak® foam moulding systems produce custom shaped cushions for products that require the consistent, precise fit of engineered protection. There is an Instapak® foam moulding solution to suit every operations, regardless of volume, throughput or configuration.

Available foam moulding models include the iMold, Moulding Wheel, and Twin Vertical System.

For applications that require a consistent, precise fit with uncommon shapes or dimensions, our experts can design and develop custom mould solutions with an integral workstation at one of our Packaging Application Centres.

- Creates custom moulded foam cushions

- Various models and speeds fit unique needs

- Instapak® on-demand foam technology provides an economic solution that doesn't compromise on product protection

02 Product Lines

- Product Range

- Instapak iMold Foam System

FOAM MOULDING SYSTEMS

Compare Our Product Lines

Instapak® iMold Foam System

The fully automated SEALED AIR® brand Instapak® iMold foam system instantly creates engineered, pre-moulded Instapak® foam cushions. Patented Foam Dispersion Technology guarantees cushion consistency and integrity by dispensing Instapak® foam where it’s needed most, while eliminating material waste. Operators only need to select a mould option with the desired number of cushions and the Instapak® iMold system does all the work.

Instapak® iMold Foam System

The fully automated SEALED AIR® brand Instapak® iMold foam system instantly creates engineered, pre-moulded foam cushions. Patented Foam Dispersion Technology guarantees cushion consistency and integrity by dispensing Instapak® foam where it’s needed most, while eliminating material waste. Operators only need to select a mould option with the desired number of cushions and the Instapak® iMold system does all the work.

- System strategically dispenses foam throughout the bag, allowing the production of a wide variety of cushion designs

- RFID technology automatically recognises mould changeovers and loads the correct cushion recipe

- Easy-to-use touchscreen display minimises setup

- Unique cushion ejection system frees up personnel to pack and ship, rather than monitor cushion production

- Electrical: 380-415 VAC, 16A, 3 Phase, N, earth

- Receptacle type: CEE 17 (5- Pole, 16A) UL and CE approved

- System size: 117 cm W x 100 cm D x 165 cm H